Description

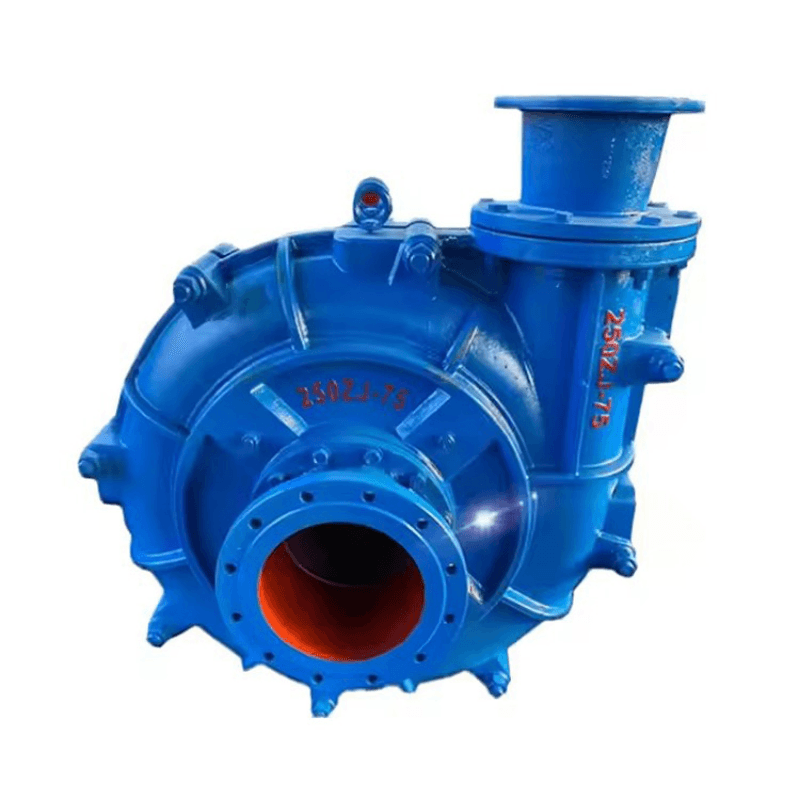

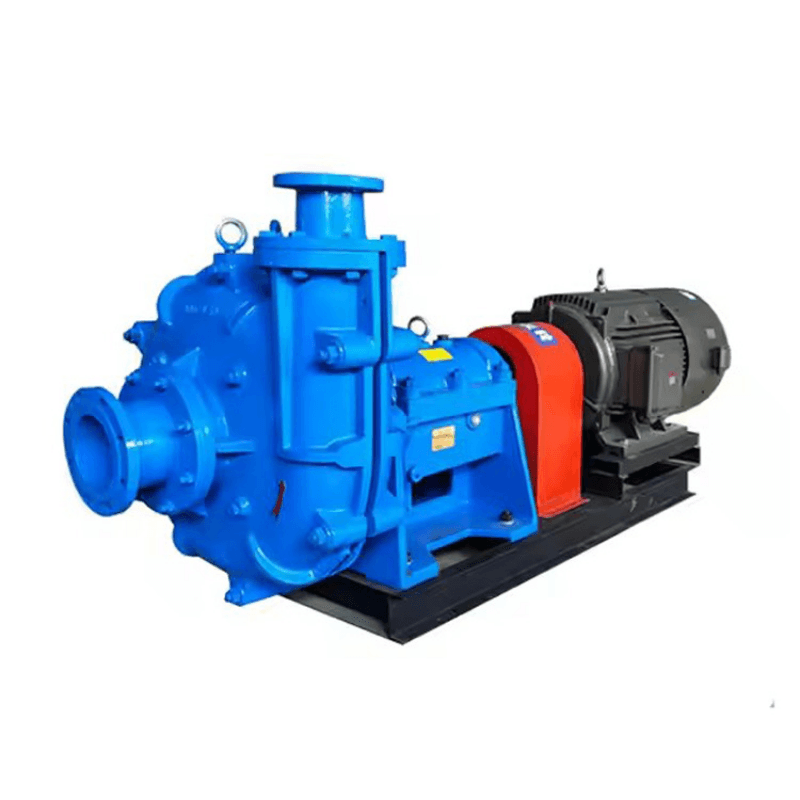

Our Centrifugal Slurry Pump features single-stage single-suction design. It comes in both horizontal and vertical models. Horizontal pumps offer 40-300mm discharge sizes. Vertical models provide 50-150mm discharge sizes. The pump body uses double-metal construction. Its vertical split case enables easy maintenance. The discharge outlet rotates eight positions. You can adjust it in 45-degree increments. This ensures perfect piping alignment. The Centrifugal Slurry Pump simplifies installation. It adapts to various layout requirements. You get complete configuration flexibility.

The pumps feature optimized structure and hydraulic design. Flow-passing components use high-chromium alloy iron or rubber. You can select different sealing methods. Choose packing seals, expelling ring seals, or mechanical seals. Composite seals are also available. These pumps deliver high operating efficiency. Their rational structure ensures lightweight construction. They provide long service life and reliable operation. The pumps produce low noise levels. They allow easy installation and maintenance. Multiple industries widely use these pumps. They serve steel, metallurgy, mining, and power sectors. They also work in coal and building materials industries. The pumps handle abrasive slurries, ash, and ore pulp. They manage weight concentrations up to 45% and 60%. The series supports various process arrangements. You can configure multiple pumps in series. Parallel or compound operation modes are also possible. All performance indicators reach advanced domestic levels.

We maintain stable and reliable product quality. Our company obtained ISO-9001 quality management system certification in 1999.

| Product Name | Horizontal Centrifugal Slurry Pump |

|---|---|

| Capacity | 10-2400m3/h |

| Head | 2-110m |

| Power | 3- 250kw |

| Speed | 490-2900r/min |

| Inlet diameter | 40-400mm |

| Outlet diameter | 40-300mm |

| Material | cast lron |

| Max temperature | 60℃ |

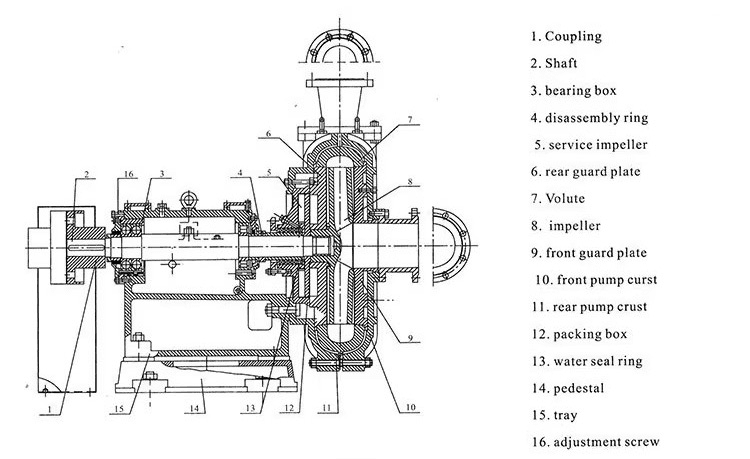

Horizontal Centrifugal Slurry Pump Structure

Superior Wear Resistance for Long Service Life

Flow passage parts use high-chromium alloy iron. This material offers excellent abrasion resistance. It provides strong corrosion protection. The components withstand heavy impacts. They handle solid particles effectively. The pump fights abrasive slurry wear. It resists corrosive media damage. This extends pump service life significantly. The Centrifugal Slurry Pump maintains performance. It reduces part replacement frequency. You save considerably on maintenance costs. This durability means better value.

Multiple Sealing Options for Zero Leakage

We offer various sealing methods. Choose dynamic pressure reduction seals. Select traditional packing seals. Consider expelling ring seals. Prefer mechanical seals. Each option prevents slurry leakage. Dynamic seals reduce water usage. Mechanical seals ensure maximum reliability. The Centrifugal Slurry Pump stays clean. It protects your work environment. You avoid messy leak problems. Our experts help choose proper seals. This guarantees optimal performance.

Flexible Drive and Configuration Options

The pump supports multiple drive types. Use direct coupling connection. Choose belt drive system. Consider hydraulic drive option. Select variable frequency drive. You can connect pumps in series. They also work in parallel arrangements. This meets diverse operational needs. The Centrifugal Slurry Pump adapts perfectly. It fits your specific requirements. You achieve ideal system configuration. This versatility provides excellent solutions.

Easy Maintenance and Wide Performance Range

The bearing component uses cylindrical design. It allows easy impeller adjustment. You can remove it completely for service. Grease lubrication simplifies maintenance. The pump delivers wide flow range. It handles 4-3000 cubic meters hourly. Head reaches 130 meters maximum. Multi-stage series operation enables long-distance transport. The Centrifugal Slurry Pump works efficiently. It ensures reliable performance. You get smooth operation always.

Proven Reliability in Tough Conditions

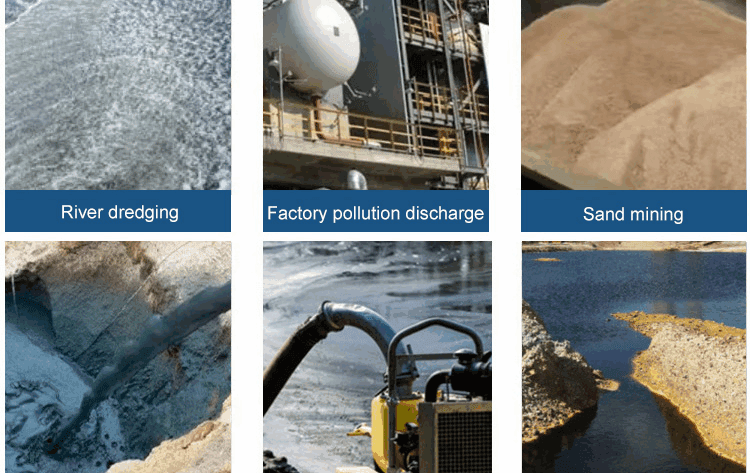

The pump operates with minimal vibration. It produces very low noise. This Centrifugal Slurry Pump runs reliably. It handles severe working conditions. The unit serves multiple industries. It works in power generation plants. It serves metallurgical operations. Coal processing uses our pumps. Building materials industry applies them. The pump handles ash slurry at 45% concentration. It manages ore pulp at 60% concentration. Media temperature stays below 60°C. This Centrifugal Slurry Pump delivers consistent results.

Perfect for Multiple Industrial Applications

Reviews

There are no reviews yet.