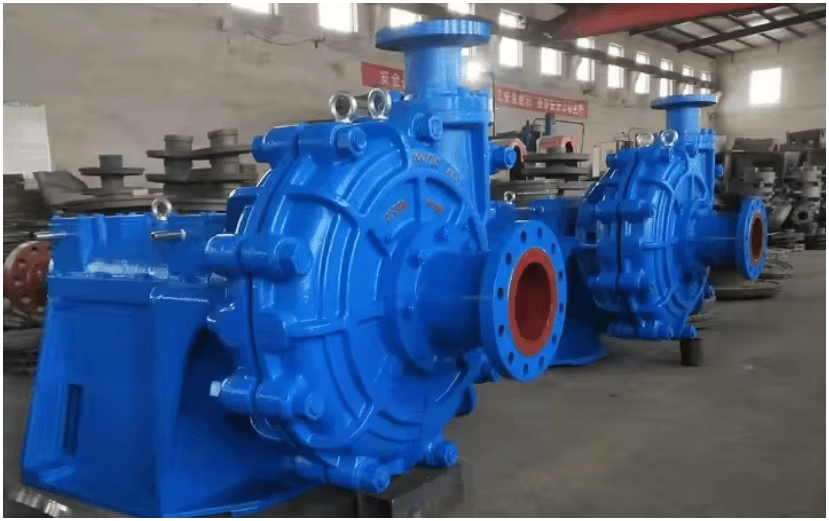

Description

ZGB Submersible Slurry Pump

Introduction to Submersible Slurry Pump

A submersible slurry pump handles abrasive and corrosive fluids. It works fully submerged in liquid. This design ensures efficient pumping. Our submersible slurry pump uses modern CAD methods. It delivers excellent hydraulic performance. You get high efficiency and low wear. The pump has spacious flow channels. These prevent clogging issues. Superior cavitation resistance improves operation. We combine auxiliary impeller and packing seals. Mechanical seals ensure zero leakage. Reliability design boosts mean time between failures. Oil-lubricated metric bearings run cool. Proper lubrication and cooling systems help. Wetted parts use special materials. They resist wear and corrosion. Special treatment suits seawater and salt spray. You can use multiple pumps in series. Maximum pressure reaches 3.6 MPa. Choose our submersible slurry pump for durability.

| Type | Max. Power (Kw) | Clear Water Performance | Handled Particle Dia. | ||||

|---|---|---|---|---|---|---|---|

| Capacity | Head | Speed | Max.eff. | (NPSH)r | Max. (mm) | ||

| (m3/h) | (m) | (r/min) | (%) | (m) | |||

| 40ZJ-I-A17 | 7.5 | 4.5-23.4 | 9.1-44.6 | 1400-2900 | 52.4 | 2.5 | 11 |

| 50ZJ-I-A46 | 55 | 23-94 | 17.9-85.8 | 700-1480 | 44.7 | 1.4 | 14 |

| 65ZJ-I-A30 | 15 | 23-79 | 7.4-34.8 | 700-1460 | 63.5 | 2 | 19 |

| 80ZJ-I-A36 | 45 | 46-190 | 9.6-51.4 | 700-1480 | 67.7 | 2.5 | 24 |

| 100ZJ-I-B42 | 90 | 83-365 | 12.7-66.8 | 700-1480 | 71.6 | 2.5 | 40 |

| 150ZJ-I-C42 | 132 | 142-550 | 12.1-62.8 | 700-1480 | 77.1 | 2.2 | 69 |

| 200ZJ-I-A65 | 250 | 235-950 | 16.4-72.0 | 490-980 | 79.6 | 2.5 | 62 |

| 250ZJ-I-A85 | 800 | 376-1504 | 30.1-128.7 | 490-980 | 76.5 | 3.5 | 76 |

| 300ZJ-I-A100 | 450 | 464-1826 | 15.3-65.2 | 300-590 | 81.1 | 3 | 88 |

| 350ZJ-I-C104 | 560 | 1335-3300 | 36.6-66.9 | 490-590 | 77.6 | 7.3 | 180 |

Key Features of Our Submersible Slurry Pump

Our submersible slurry pump offers many benefits. Modern CAD design enhances hydraulic efficiency. It reduces wear rates significantly. Spacious flow channels avoid blockages. They handle thick slurries easily. Cavitation performance stands out. Seals combine auxiliary impeller and packing. Mechanical options prevent leaks completely. Reliability engineering increases uptime. Mean time between failures grows. Oil-lubricated metric bearings ensure smooth operation. Lubrication and cooling systems maintain low temperatures. Wetted parts feature special alloys. They withstand abrasion and chemical attack. Special coatings fight seawater corrosion. Multi-stage series operation is possible. It supports pressures up to 3.6 MPa. These features make our pump superior.

Applications and Use Cases

Our submersible slurry pump serves various industries. Mining operations use it for tailings. It pumps abrasive slurries efficiently. The pump works in construction dewatering. It handles muddy water and sand. Industrial plants employ it for waste transfer. Corrosive fluids move safely. Marine applications include seawater pumping. Special materials resist salt damage. Agriculture uses it for irrigation with sediments. The pump manages high-solid content. Wastewater treatment plants rely on it. It moves sludge without clogging. Dredging projects benefit from its power. Series setups handle high heads. Always ensure proper installation for best results.

Why Choose Our Submersible Slurry Pump

Select our submersible slurry pump for reliability. Advanced CAD design ensures top performance. You achieve higher efficiency rates. Low wear means longer life. Spacious flow channels reduce downtime. No clogging issues occur. Excellent cavitation resistance protects the pump. Sealing systems stop leaks entirely. This prevents environmental contamination. Reliability design cuts maintenance costs. Mean time between failures extends. Bearings run cool with oil lubrication. Cooling systems prevent overheating. Special materials fight wear and corrosion. They last in harsh conditions. Multi-stage use offers flexibility. It meets high-pressure needs up to 3.6 MPa. Our pump delivers consistent results.

Conclusion and Call to Action

It combines modern design with robust features. You get efficiency and durability. Use it in mining, marine, and more. The pump resists clogging and corrosion. Seals ensure leak-free operation. Bearings stay cool for reliability. Special materials handle abrasion. Series use supports high pressure. Invest in our submersible slurry pump today. Contact us for details and pricing. Improve your operations with quality equipment.

Reviews

There are no reviews yet.