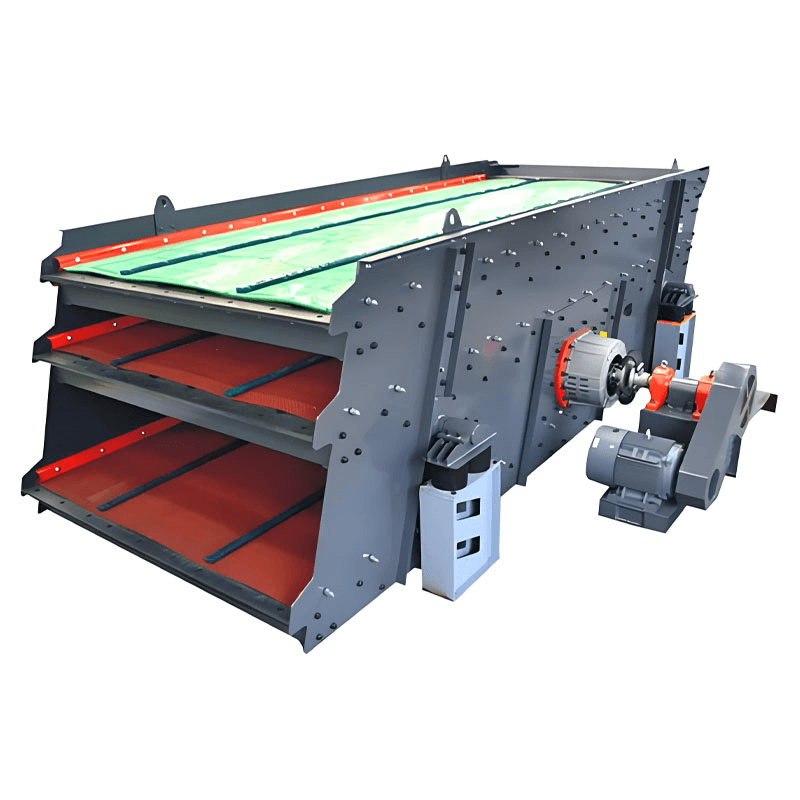

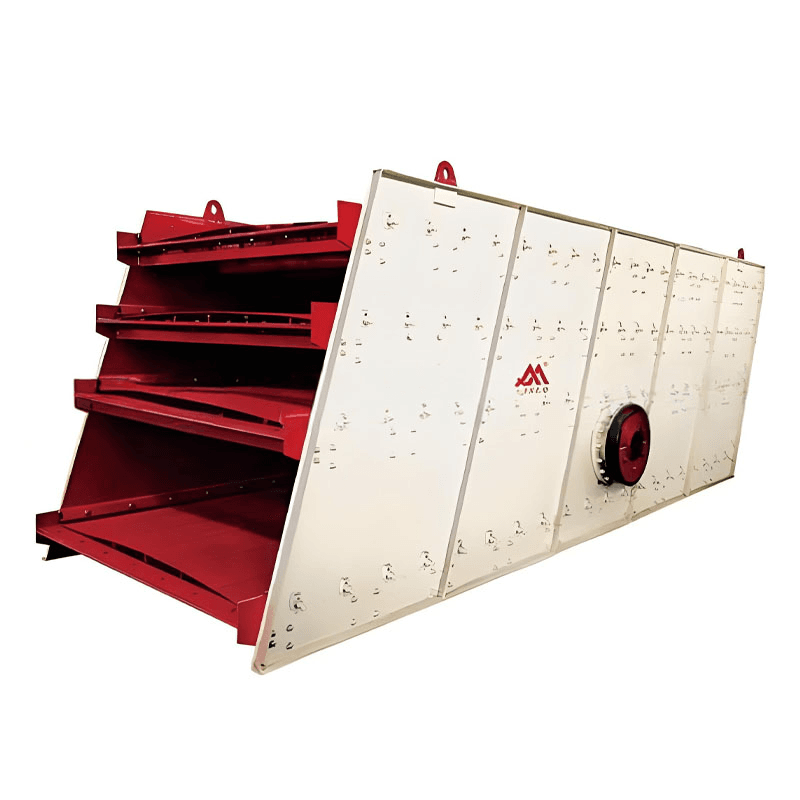

Powerful Screening Performance

Our YA Circular Vibrating Screen works exceptionally well. An electric motor drives the eccentric vibrator. This action creates strong centrifugal inertia force. The screen box then moves in a circular vibration path. You can easily adjust the screen surface angle. This flexibility ensures a long material flow line. It achieves very high screening efficiency. The machine handles big capacities from 100 to 1700 tons every hour. Its screening area ranges from 7.5 to 14 square meters. This means faster processing for your business. You get more work done in less time. The design focuses on maximum productivity. It saves you both time and energy.

| Technical parameters of YA circular vibrating screen | |

|---|---|

| Rotate speed | 700~850rpm |

| Amplitude | 5~12mm |

| Excitation force | Up to 3.5G |

| Inclination | 15~23° |

| Grading granularity | 1~130mm |

| Maximum admission granularity | 200mm |

Robust Construction and Easy Maintenance

We build this vibrating screen for long life. Its structure uses a fully bolted design. There are no welded parts for easy assembly. The screen mesh comes in two main types. Choose woven mesh for YA/2YA models. Choose punch plate mesh for the YAH type. Replacing these screens is simple and fast. Our machine features a complete shock absorption system. Special springs reduce noise significantly. They also minimize impact on your foundation. This thoughtful design prevents future problems. You will enjoy smooth operation daily. Maintenance needs are very low. This machine is a reliable partner.

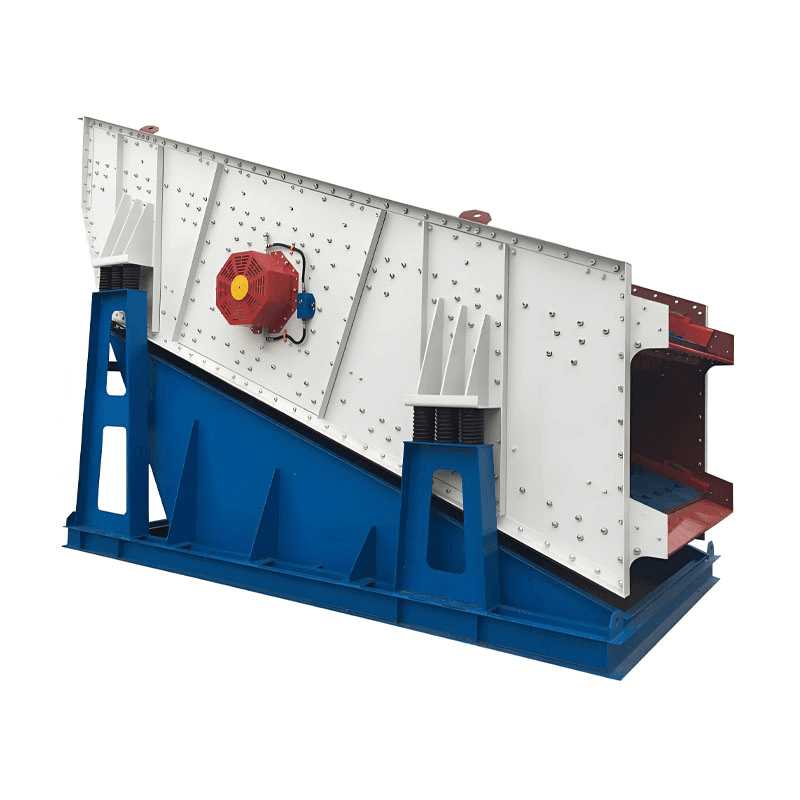

Flexible Adjustment and Strong Durability

Adapt the machine to your specific needs. You can change vibration amplitude easily. Adjust the eccentric blocks from 7mm to 9mm. This suits various material types perfectly. Our screen also fights clogging effectively. We use spring steel woven mesh. Another option is wear-resistant rubber mesh. Both choices offer high vibration intensity. Materials flow smoothly without blockage. This ensures continuous operation. You avoid frequent stops for cleaning. The machine withstands tough conditions. Its durability saves you money over time. Enjoy consistent performance every day.

Safe Operation and Environmental Care

Safety is our top priority. The machine runs with very low noise. We use low-stress reduction springs. They absorb vibrations effectively. This creates a quieter work environment. Some models offer a fully enclosed structure. This design contains dust completely. It stops powder from flying into the air. Your workplace stays clean and safe. You protect your workers’ health. You also meet strict environmental standards. Our screen promotes sustainable production. It shows your care for the planet. Choose a cleaner, safer screening solution.

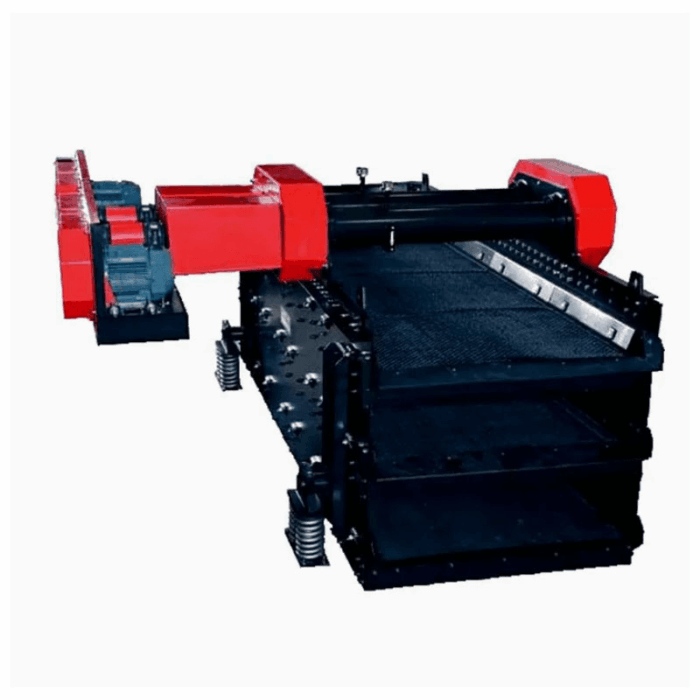

Wide Range of Applications

Use our YA screen for many different tasks. It is perfect for size classification of materials. Screen coal, coke, and limestone efficiently. The machine also handles dewatering processes. It works well for desliming operations too. Many industries benefit from its versatility. Mining and quarrying sites love it. Construction and aggregate plants use it daily. It fits into various production lines seamlessly. You can rely on it for consistent results. This screen becomes your go-to equipment. It handles multiple jobs with ease.

Why Choose Our YA Vibrating Screen?

Our company focuses on quality and innovation. We have years of experience in manufacturing. Every screen undergoes strict testing. We ensure high performance and reliability. Our team provides excellent customer support. We help you choose the right model. We also offer quick installation guidance. You get professional service always. Our products have a strong market reputation. Clients trust our brand for good results. We value long-term partnerships. Your success is our main goal.

Easy Ordering and Support

Getting your YA screen is simple. Visit our website for more details. Check the full product specifications. Contact our sales team for a quote. We respond to your inquiries quickly. We offer competitive pricing and terms. Our service does not end with sales. We provide comprehensive after-sales support. This includes spare parts supply. We also provide maintenance advice. Trust us for a smooth experience from start to finish. Let us help you improve your screening process today. Contact us to inquire about your project.