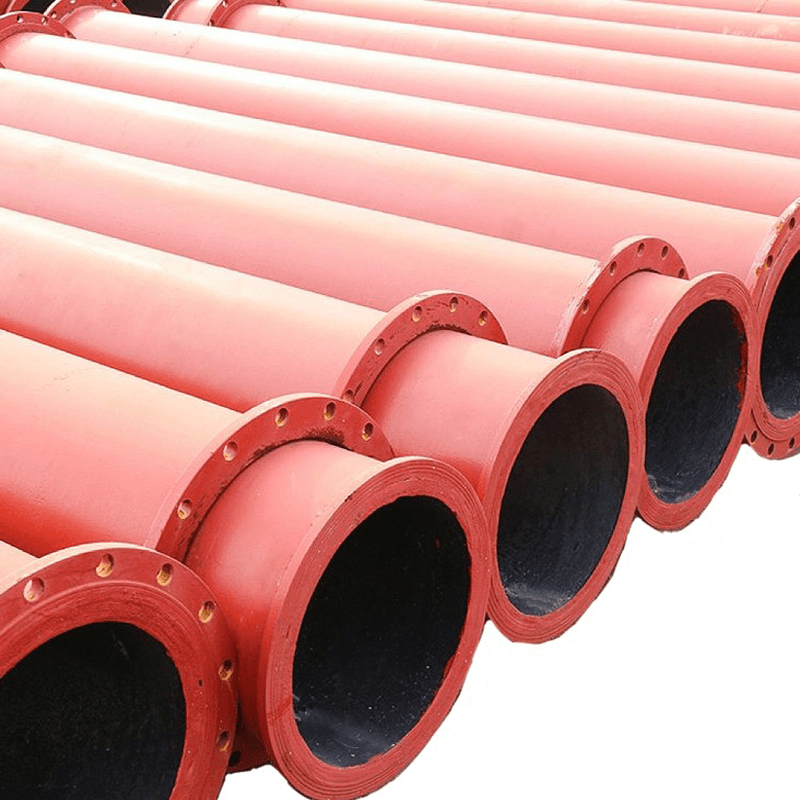

Ceramic Lined Wear-resistant Pipe

| Number | pipe diameter | pipe wall thickness | Wear-resistant layer thickness | Number | pipe diameter | pipe wall thickness | Wear-resistant layer thickness |

|---|---|---|---|---|---|---|---|

| 1 | 68 | 8 | 4 | 18 | 168 | 8 | 4 |

| 10 | 4 | 10 | 4 | ||||

| 2 | 70 | 8 | 4 | 19 | 180 | 8 | 4 |

| 10 | 4 | 10 | 4 | ||||

| 3 | 73 | 8 | 4 | 20 | 194 | 8 | 4 |

| 10 | 4 | 10 | 4 | ||||

| 4 | 76 | 8 | 4 | 21 | 203 | 8 | 4 |

| 10 | 4 | 10 | 4 | ||||

| 5 | 83 | 8 | 4 | 22 | 219 | 10 | 4 |

| 10 | 4 | 12 | 5 | ||||

| 6 | 89 | 8 | 4 | 23 | 245 | 10 | 4 |

| 10 | 4 | 12 | 5 | ||||

| 7 | 95 | 8 | 4 | 24 | 273 | 10 | 4 |

| 10 | 4 | 12 | 5 | ||||

| 8 | 102 | 8 | 4 | 25 | 299 | 10 | 4 |

| 10 | 4 | 12 | 5 | ||||

| 9 | 108 | 8 | 4 | 26 | 325 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 10 | 114 | 8 | 4 | 27 | 351 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 11 | 121 | 8 | 4 | 28 | 377 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 12 | 127 | 8 | 4 | 29 | 402 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 13 | 133 | 8 | 4 | 30 | 426 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 14 | 140 | 8 | 4 | 31 | 480 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 15 | 146 | 8 | 4 | 32 | 500 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 16 | 152 | 8 | 4 | 33 | 530 | 12 | 5 |

| 10 | 4 | 14 | 6 | ||||

| 17 | 159 | 8 | 4 | 34 | 630 | 12 | 5.5 |

| 10 | 4 | 14 | 6 |

Exceptional Wear Resistance for Maximum Longevity

Our Ceramic Lined Wear-resistant Pipe provides extreme wear resistance. Its ceramic layer reaches HV1100 hardness. This material withstands abrasion perfectly. Specifically, it lasts 15-20 times longer than standard steel pipes. Consequently, it handles high-speed material scouring easily. Moreover, the pipe resists severe impact damage. Therefore, you get dramatically extended service life. Furthermore, replacement frequency drops significantly. Similarly, your maintenance costs decrease substantially. Ultimately, this Ceramic Lined Wear-resistant Pipe maintains excellent performance over time, ensuring reliable operation for your business.

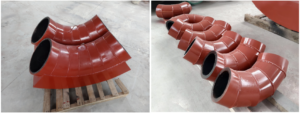

Superior Composite Structure with Enhanced Performance

This pipe features a unique three-layer design. Specifically, it combines alumina ceramic, transition layer and steel pipe. This structure offers the best properties. The ceramic interior provides outstanding wear resistance. Additionally, it demonstrates excellent corrosion resistance. Meanwhile, the steel shell ensures high mechanical strength. Moreover, it maintains superb impact resistance. Consequently, the pipe withstands both abrasion and physical shocks. Therefore, you receive comprehensive protection for your systems. Furthermore, this Ceramic Lined Wear-resistant Pipe delivers unmatched durability in toughest conditions.

Smooth Interior Surface for Optimal Flow Efficiency

The ceramic lining creates a mirror-smooth surface. This characteristic reduces flow resistance significantly. Consequently, material moves through easily. Moreover, scaling and blockages decrease dramatically. Therefore, your system maintains peak efficiency. Additionally, energy consumption drops notably. Furthermore, throughput increases substantially. Thus, this Ceramic Lined Wear-resistant Pipe improves overall operational efficiency while reducing your power costs.

Lightweight Design for Easy Installation

Compared to traditional steel pipes, this product weighs much less. Specifically, it reduces weight substantially. Consequently, handling becomes much easier. Moreover, transportation costs decrease notably. Additionally, installation requires less labor. Therefore, you save time and money. Furthermore, support structure needs simplify. Thus, this Ceramic Lined Wear-resistant Pipe offers convenient implementation while lowering your project expenses.

Advanced Manufacturing Process for Perfect Bonding

We use unique SHS centrifugal technology. This process creates metallurgical bonding between layers. Specifically, the ceramic and steel join permanently. Consequently, the lining remains secure always. Moreover, it never detaches during operation. Therefore, safety improves significantly. Furthermore, service life extends remarkably. Thus, this Ceramic Lined Wear-resistant Pipe guarantees reliable performance through advanced production methods.

Ideal Applications Across Multiple Industries

Our Ceramic Lined Wear-resistant Pipe serves various sectors perfectly. Mining operations benefit greatly. It transports tailings and concentrates efficiently. Power plants use it for ash handling. Additionally, coal slurry lines perform better. Cement plants move raw meal effectively. Steel mills handle abrasive wastes easily. Dredging operations achieve superior results. Moreover, chemical processing works perfectly. Therefore, this pipe suits numerous applications. Furthermore, it adapts to different materials easily. Thus, our Ceramic Lined Wear-resistant Pipe provides versatile solutions for your specific needs.

Reliable Manufacturer with Quality Commitment

Our company focuses on excellence. We use premium materials always. Our engineers possess deep expertise. They understand industrial challenges perfectly. We provide professional technical support. Moreover, our service team responds quickly. We guarantee timely delivery worldwide. Therefore, customers trust our products completely. This Ceramic Lined Wear-resistant Pipe performs excellently everywhere. We build lasting client relationships. Your success remains our priority. Choose our solutions for superior results. We guarantee your complete satisfaction with our products and services.