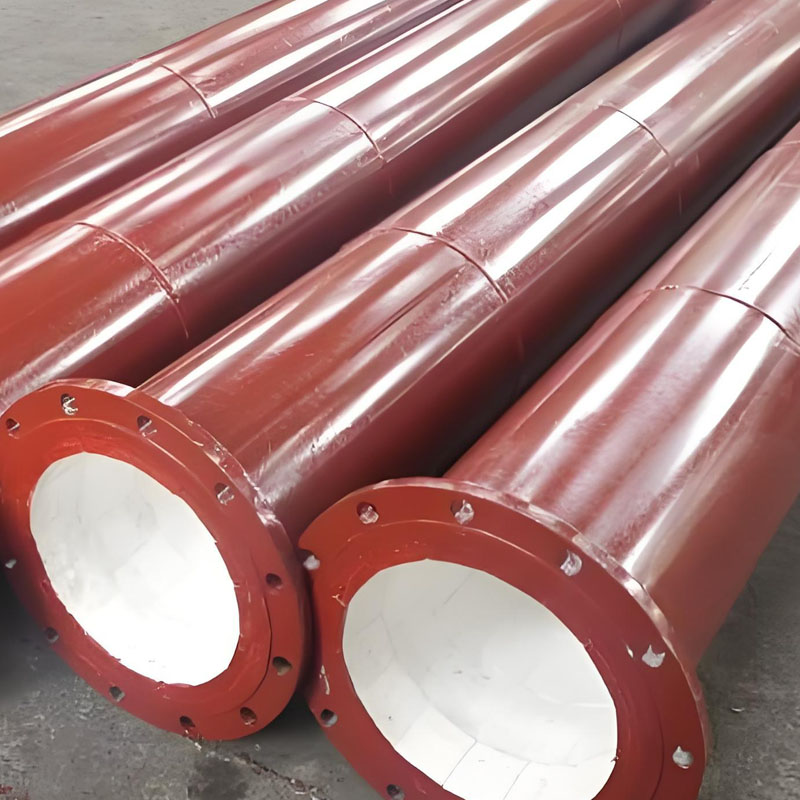

Introduction to Wear-Resistant Patch Tube

Our Wear-Resistant Patch Tube offers exceptional performance. It features advanced ceramic technology. This tube handles tough industrial environments. It combines strength with lightweight design. You get long-lasting service from this product. Many industries trust our solution. It reduces maintenance needs effectively. The tube ensures reliable operation daily. Choose our Wear-Resistant Patch Tube for better results. It saves you money over time. Our team designs each tube carefully. We focus on quality and durability. This product meets high standards. It is perfect for abrasive conditions. You will see improved efficiency soon. Invest in our Wear-Resistant Patch Tube today. It delivers top value always.

| Ceramic patch wear -resistant pipe parameters | ||||

| Specification | Outer Diameter | Inside Diameter | Wall Thickness | Steel Pipe Thick |

| DN80 | 112-132 | 80 | 10~14 | 6~12 |

| DN100 | 132~152 | 100 | 10~14 | 6~12 |

| DN125 | 157~177 | 125 | 10~14 | 6~12 |

| DN150 | 182~202 | 150 | 10~14 | 6~12 |

| DN200 | 236~264 | 200 | 10~20 | 6~12 |

| DN250 | 286~314 | 250 | 10~20 | 6~12 |

| DN300 | 336~364 | 300 | 10~20 | 6~12 |

| DN350 | 386~414 | 350 | 10~20 | 6~12 |

| DN400 | 436-464 | 400 | 10~20 | 6~12 |

| DN450 | 486~514 | 450 | 10~20 | 6~12 |

| DN500 | 542~584 | 500 | 15~30 | 6~12 |

| DN600 | 642~684 | 600 | 15~30 | 6~12 |

| DN700 | 742~784 | 700 | 15=30 | 6~12 |

| DN800 | 842~884 | 800 | 15-30 | 6~12 |

| DN900 | 942~984 | 900 | 15-30 | 6~12 |

| DN1000 | 1046~1088 | 1000 | 15-30 | 8~14 |

| DN1200 | 1246~1288 | 1200 | 15-30 | 8~14 |

| DN1400 | 1446~1488 | 1400 | 15~30 | 8~14 |

| DN1600 | 1646~1688 | 1600 | 15-30 | 8~14 |

| DN1800 | 1846~1888 | 1800 | 15-30 | 8~14 |

| DN2000 | 2046~2088 | 2000 | 15~30 | 8~14 |

Superior Wear Resistance

This tube resists wear extremely well. It uses alumina ceramic lining. The Mohs hardness reaches 9.0. It outlasts standard steel pipes. Wear resistance is twenty times higher. It withstands high-speed fluids. Solid particles cause no damage. Your systems run smoothly longer. This reduces downtime significantly. The ceramic layer fights abrasion. It keeps the interior intact. You get consistent performance. Our Wear-Resistant Patch Tube endures harsh conditions. It cuts replacement costs greatly. Many users report fewer failures. This feature ensures product longevity. Trust our tube for heavy use.

Wide Temperature Range

Our tube operates in extreme temperatures. It works from -50°C to 700°C. This range suits hot environments. Power plants use it safely. It performs well in cold too. Thermal stability is guaranteed. You can rely on it consistently. The materials do not degrade. They handle sudden changes easily. This prevents leaks and breaks. Your processes remain uninterrupted. The Wear-Resistant Patch Tube supports high heat tasks. It is ideal for combustion systems. Cold storage applications benefit too. Enjoy peace of mind always. Our product adapts to your needs.

Robust Structural Design

We build this tube with three layers. The alumina ceramic provides hardness. A transition layer adds strength. The steel layer offers toughness. This design balances both qualities. It makes the tube very durable. Weight drops by twenty to fifty percent. Handling becomes simpler. Installation is faster too. The structure resists impacts well. It does not crack under pressure. You get a reliable product. Our Wear-Resistant Patch Tube lasts for years. It supports heavy loads easily. This design reduces overall costs. Choose it for better performance.

Low Fluid Resistance

The inner surface is very smooth. Resistance coefficient is just 0.0193. Fluids flow with ease. This lowers energy consumption. Your pumps work less hard. Operating costs decrease greatly. The tube minimizes friction loss. It enhances system efficiency. You save on power bills. Our Wear-Resistant Patch Tube boosts productivity. It is perfect for slurry transport. Water systems benefit too. The smooth lining prevents buildup. Maintenance needs drop sharply. Enjoy faster flow rates always. This feature pays back quickly.

Easy Installation

You can install our tube many ways. Welding works well. Flanges offer flexibility. Quick connectors save time. This versatility cuts labor hours. Project costs fall by thirty percent. Your team finishes jobs faster. No special tools are needed. The process is straightforward. Our Wear-Resistant Patch Tube fits existing systems. It reduces setup delays. You start operations sooner. We provide clear instructions. Retrofitting is simple too. This ease speeds up projects. Choose our tube for hassle-free use.

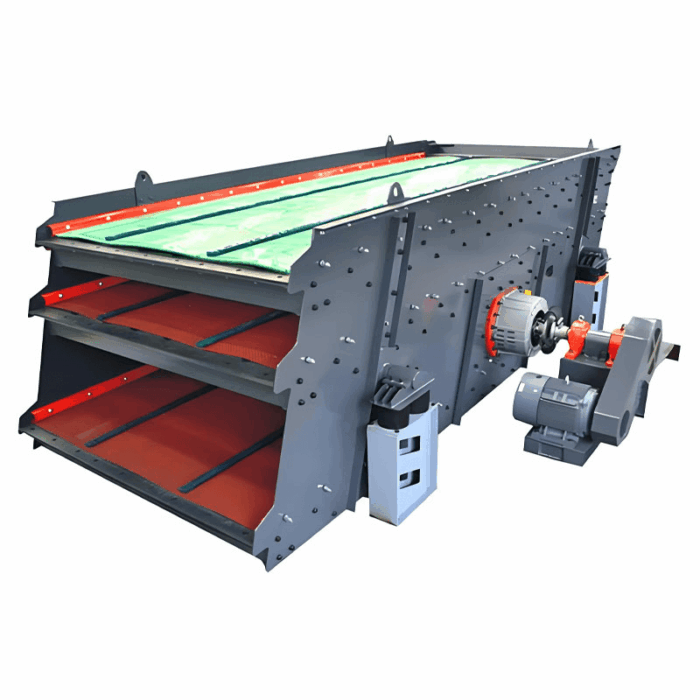

Diverse Application Scenarios

Use our tube in power plants. It excels in ash handling systems. Mining operations rely on it. Chemical plants find it useful. It transports abrasive materials safely. The tube works in pneumatic conveying. Water treatment plants use it. It handles sand and granules. Industrial processing benefits greatly. Our Wear-Resistant Patch Tube suits many fields. It performs in harsh environments. You can apply it widely. This versatility makes it popular. Many clients report success. It solves wear problems effectively.

Why Choose Our Products

We have years of experience. Our factory uses top technology. We offer custom solutions. Quality control is strict. Each tube undergoes testing. We provide excellent customer service. Our team supports you always. Delivery times are short. Prices are competitive. You get great value. It meets global standards. Clients trust our brand. We ensure satisfaction. Choose us for reliable partnerships. Your success is our goal.