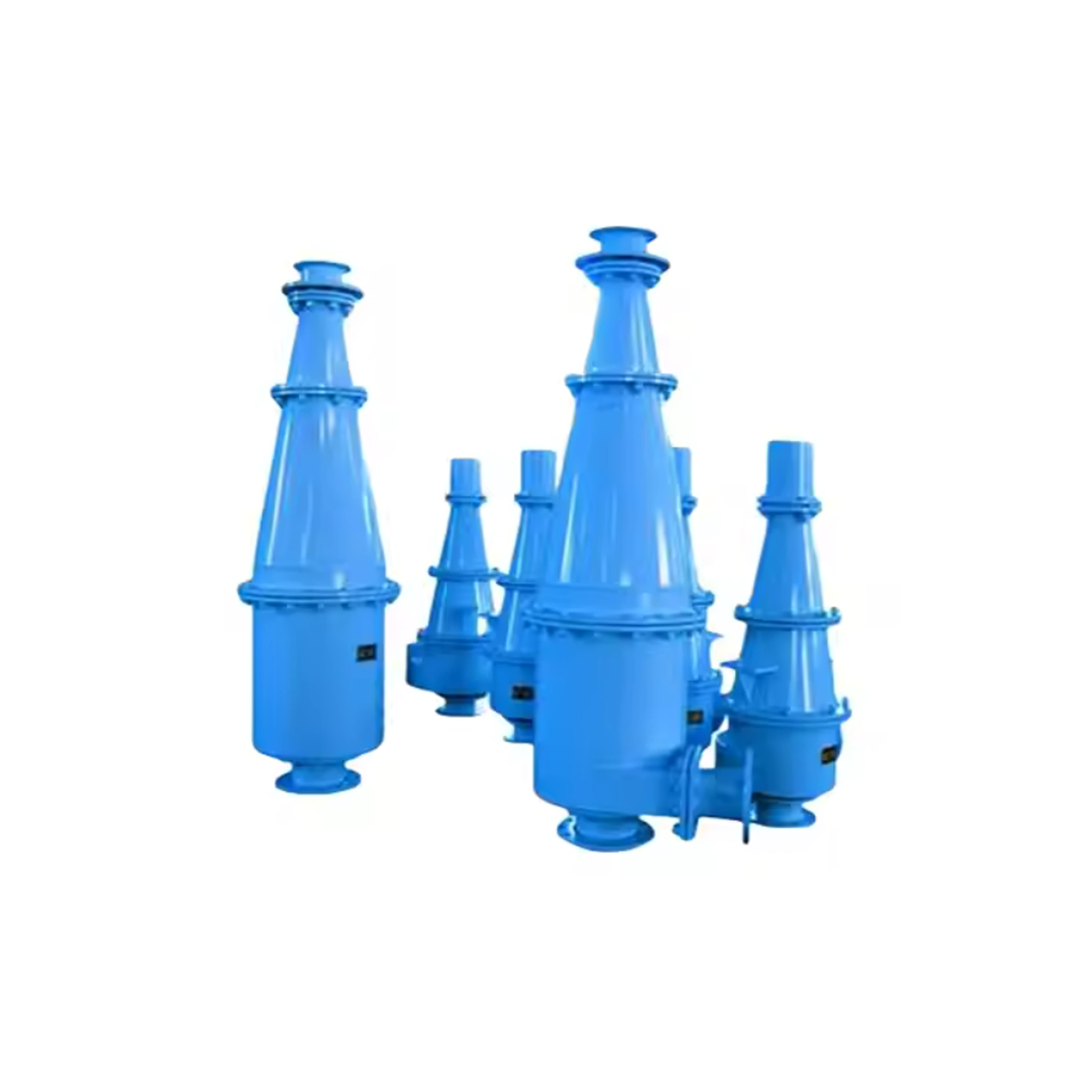

Product Overview

Our Wear Resistant FX Cyclone delivers exceptional performance. This robust device handles various materials efficiently. It ensures reliable separation in multiple industries. You can trust its wear-resistant features. The cyclone offers customized structural designs. Choose from different models and sizes. It provides high grading accuracy. Maintenance is straight forward and quick. Our team supports all your needs. The FX series guarantees long service life. Use it for demanding applications. It reduces operational downtime. The design prioritizes user convenience. We focus on quality and efficiency. Your satisfaction is our top goal. The cyclone adapts to your requirements. It features advanced technology. Experience superior results today. Invest in our Wear Resistant FX Cyclone. It maximizes your productivity. The product is built to last. We ensure timely delivery. Our solutions are cost-effective. Trust our expertise in cyclones.

| Specification, model and technical parameters | ||||

| Specification | Diameter | Feed pressure | Processing power | separation size |

| HZ710 | 710 | 0.04-0.15 | 350-500 | 74-250 |

| HZ660 | 710 | 0.04-0.15 | 250-360 | 74-250 |

| HZ610 | 610 | 0.04-0.15 | 200-300 | 74-200 |

| HZ500 | 500 | 0.04-0.2 | 140-240 | 74-200 |

| HZ400 | 400 | 0.06-0.2 | 100-170 | 74-150 |

| HZ350 | 350 | 0.06-0.2 | 70-150 | 50-150 |

| HZ300 | 300 | 0.06-0.2 | 45-90 | 50-150 |

| HZ250 | 250 | 0.06-0.3 | 40-80 | 40-100 |

| HZ200 | 200 | 0.06-0.3 | 25-40 | 40-100 |

| HZ150 | 150 | 0.08-0.3 | 15-30 | 20-74 |

| HZ100 | 100 | 0.1-0.3 | 8~15 | 20-50 |

| HZ75 | 75 | 0.1-0.4 | 45785 | 10-40 |

Customized Design and Series

We offer personalized structural designs. Select based on your material properties. Our Wear Resistant FX Cyclone has many options. Choose from Y series for pre-classification. The P series provides flat bottom designs. B series includes multi-cone structures. Models range from Φ10 to Φ840mm. Separation size spans 2μm to 350μm. It meets diverse production scales. The series supports large operations. You can find the perfect fit. We customize for specific conditions. The design enhances material flow. It minimizes blockages and wear. Our team helps with selection. The series is fully scalable. It accommodates various feed rates. You achieve optimal performance. We use durable components. The cyclone resists abrasion well. It ensures consistent operation. Our designs reduce energy use. They improve overall efficiency. The series is industry-proven. We update models regularly. They incorporate user feedback. The FX Cyclone evolves with needs.

High Efficiency and Performance

Our Wear Resistant FX Cyclone ensures high grading efficiency. It uses small diameter designs. The cone angle is optimized. This boosts separation precision. We employ radial feed positioning. It aligns particles smoothly. Short-circuit flow is minimized. The technology enhances accuracy. Large models handle high volumes. For example, 1300mm units process 1500m³/h. You get faster throughput. The cyclone maintains steady performance. It reduces product loss. Energy consumption stays low. The device operates quietly. It fits compact spaces. We test all units thoroughly. They meet strict quality standards. Performance is repeatable and reliable. The cyclone handles tough materials. It resists clogging and wear. You see fewer disruptions. Our designs increase uptime. They support continuous processes. The FX Cyclone delivers sharp cuts. It improves end-product quality. We focus on innovation. Our cyclones set benchmarks. They outperform competitors easily.

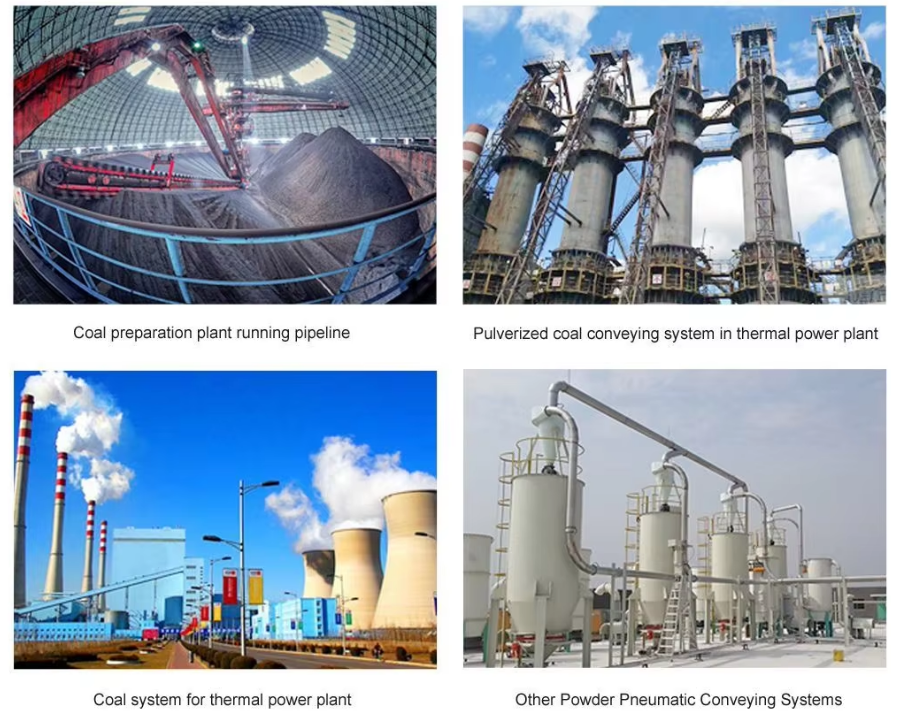

Applications in Various Industries

Use our Wear Resistant FX Cyclone in mining. It separates ores and minerals. The device works in coal processing. It handles slurry concentration. Apply it in wastewater treatment. The cyclone clarifies water efficiently. It serves chemical plants. You can use it for sand classification. The product fits aggregate production. It aids in recycling operations. Use it for desliming and degritting. The cyclone benefits food processing. It separates powders and granules. You find it in pharmaceutical setups. It ensures pure product streams. The device supports environmental projects. It reduces waste and pollution. Our cyclones work in power plants. They manage fly ash separation. Use them in metallurgy. They refine metal powders. The FX Cyclone suits many sectors. It adapts to changing needs. We provide application guidance. Our solutions are versatile. They handle abrasive materials. The cyclone operates in harsh conditions. It delivers consistent results. Trust it for critical tasks.

Why Choose Us

We use diverse wear-resistant materials. Options include ceramic linings. Polyurethane linings are available. Rubber linings offer flexibility. You select based on your needs. Our Wear Resistant FX Cyclone lasts longer. It reduces replacement costs. Maintenance is simple and fast. Adjust and easily. Installation requires minimal effort. Our team provides full support. We offer technical assistance. Spare parts are readily available. The cyclone ensures low downtime. It boosts your profitability. We have years of experience. Our products are field-tested. They receive positive feedback. We customize solutions for you. The FX series is reliable. It meets global standards. We prioritize customer service. Our delivery is prompt. Prices are competitive. We innovate continuously. The cyclone features latest tech. It is built with precision. We guarantee performance. Choose us for quality. Our reputation is strong. We partner for your success. The Wear Resistant FX Cyclone excels.