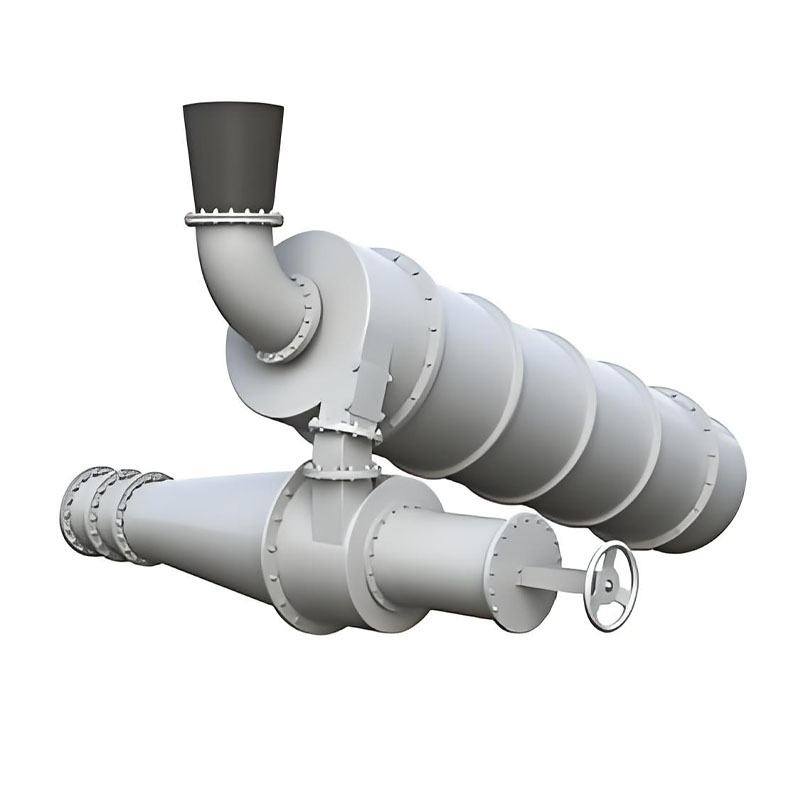

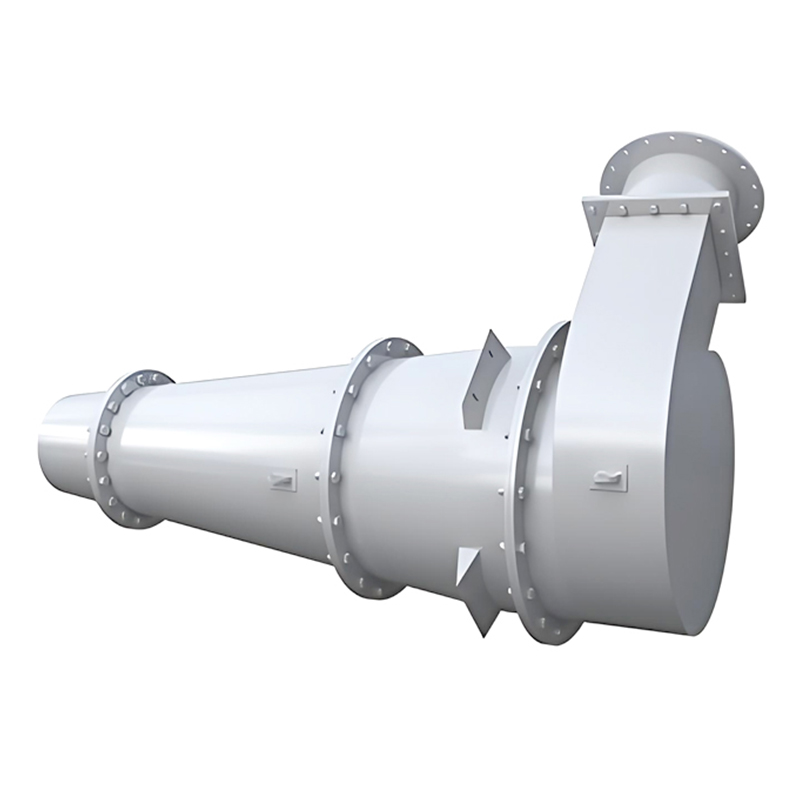

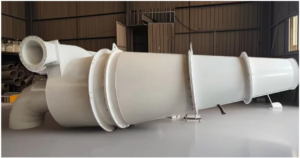

3-product Heavy Dielectric Hydrocyclone

| Unpressure three product heavy dielectric cyclone | ||||

|---|---|---|---|---|

| Dimensions | File particle size/mm | Feed pressure/MPa | processing power/(t/h) | Medium cycle volume/(m3/h) |

| WTMC500/350 | ≤20 | 0.05~0.08 | 35~50 | 140~180 |

| WTMC600/400 | ≤30 | 0.06~0.10 | 50~80 | 180~300 |

| WTMC710/500 | ≤35 | 0.08~0.12 | 80~120 | 300~420 |

| WTMC780/550 | ≤40 | 0.09~0.13 | 100~150 | 420~540 |

| WTMC850/600 | ≤45 | 0.10~0.14 | 120~180 | 480~620 |

| WTMC900/650 | ≤50 | 0.12~0.16 | 140~200 | 560~700 |

| WTMC1000/710 | ≤55 | 0.15~0.18 | 180~230 | 700~800 |

| WTMC1100/780 | ≤60 | 0.18~0.22 | 220~280 | 800~1100 |

| WTMC1200/850 | ≤70 | 0.20~0.28 | 260~350 | 1100~1400 |

| WTMC1300/920 | ≤80 | 0.22~0.30 | 320~400 | 1400~1600 |

| WTMC1400/1000 | ≤90 | 0.28~0.38 | 400~500 | 1600~2000 |

| WTMC1500/1100 | ≤100 | 0.30~0.40 | 500~600 | 2000~2400 |

| Pressure has three product heavy medium hydrocyclone | ||||

|---|---|---|---|---|

| Dimensions | File particle size/mm | Feed pressure/MPa | processing power/(t/h) | Medium cycle volume/(m3/h) |

| YTMC500/350 | ≤20 | 0.06~0.10 | 35~60 | 180~250 |

| YTMC600/400 | ≤30 | 0.08~0.12 | 50~90 | 250~370 |

| YTMC710/500 | ≤35 | 0.09~0.14 | 90~130 | 370~540 |

| YTMC780/550 | ≤40 | 0.10~0.15 | 110~160 | 540~660 |

| YTMC850/600 | ≤45 | 0.13~0.16 | 120~180 | 650~750 |

| YTMC900/650 | ≤50 | 0.15~0.18 | 160~200 | 740~840 |

| YTMC1000/710 | ≤55 | 0.18~0.22 | 200~250 | 840~1050 |

| YTMC1100/780 | ≤60 | 0.20~0.24 | 240~280 | 1050~1250 |

| YTMC1200/850 | ≤70 | 0.22~0.28 | 300~380 | 1250~1600 |

| YTMC1300/920 | ≤80 | 0.26~0.32 | 350~450 | 1600~1900 |

| YTMC1400/1000 | ≤90 | 0.30~0.40 | 450~550 | 1900~2300 |

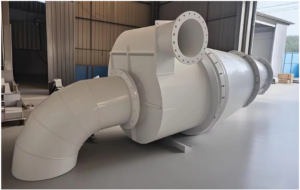

Exceptional Durability and Long Service Life

Our Heavy Dielectric Hydrocyclone features high-purity alumina ceramic lining. Specifically, this material offers superior wear resistance. As a result, it outperforms manganese steel significantly. Additionally, the lining surpasses polyurethane durability. Consequently, it withstands strong medium scouring perfectly. Moreover, the equipment handles abrasive materials easily. Therefore, this equipment lasts much longer. Furthermore, you save money on replacements. Similarly, maintenance costs decrease substantially. Ultimately, the ceramic lining maintains integrity over time, ensuring reliable performance for your operations.

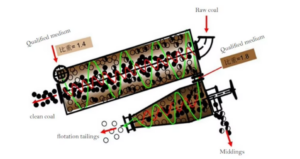

Precise Separation and Stable Performance

Firstly, the ceramic surface remains mirror-smooth. This characteristic stabilizes medium flow effectively. Consequently, it ensures consistent separation accuracy. As a result, you obtain three pure products consistently. For example, clean coal achieves high purity levels. Similarly, middlings separate perfectly. Moreover, refuse removal works efficiently. Therefore, this hydrocyclone delivers reliable results. Furthermore, operation stays stable continuously. Thus, your process maintains excellent efficiency and product quality remains consistently high.

Superior Corrosion Resistance and Wide Adaptability

Notably, ceramic material resists chemical corrosion. In particular, it handles acidic conditions perfectly. Likewise, alkaline environments cause no damage. Additionally, the equipment adapts to complex coal slurry. Moreover, various water compositions work fine. Consequently, this unit suits different mining conditions. Therefore, you can use it in multiple applications. Furthermore, performance remains consistent across various operational environments, making it a versatile solution for your plant.

Easy Maintenance and Cost-Effective Operation

Thanks to modular design, you can replace parts quickly. As a result, worn components require minimal change time. Furthermore, local repair needs little effort. Consequently, downtime reduces dramatically. Moreover, this design saves maintenance hours. Additionally, long lifespan cuts costs significantly. Therefore, single-use expense decreases notably. Ultimately, overall operating costs drop substantially, providing excellent economic benefits for your business.

Reliable Structure and Safe Operation

Through special fixation, ceramic lining remains secure. As a result, the bond maintains strength consistently. Moreover, impact resistance stays exceptionally high. Consequently, the lining never detaches during operation. Therefore, this equipment ensures complete safety. Furthermore, it runs without interruption. Thus, your production schedule maintains perfect reliability, ensuring continuous operation and workplace safety.Contact us to solve your project

Project