Introduction to Ceramic patch straight pipe

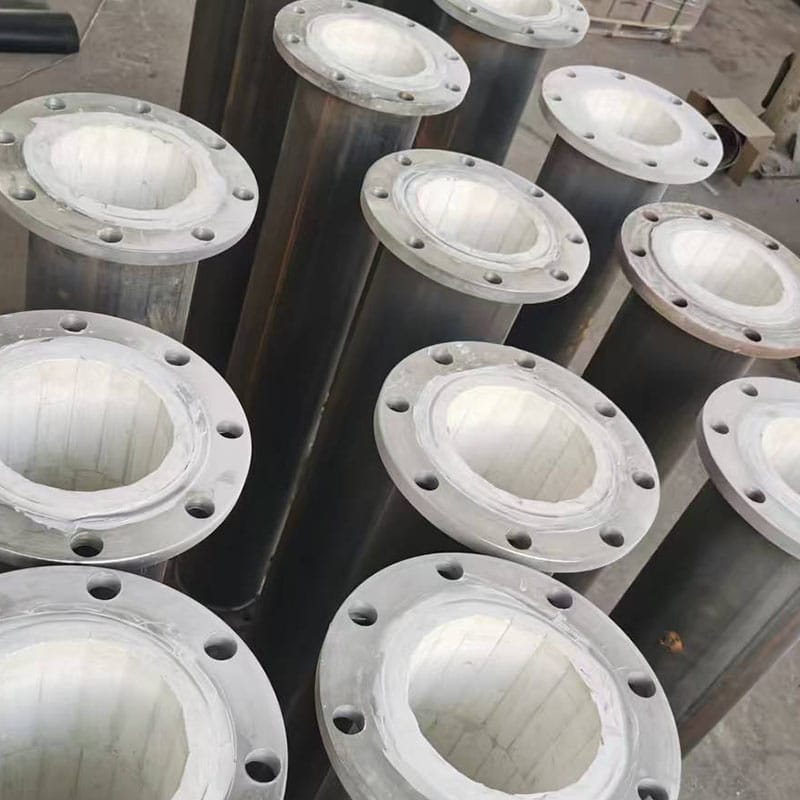

Our Ceramic Patch Straight Pipe offers exceptional performance. It is perfect for tough industrial environments. This pipe features high-quality alumina ceramic. It ensures long-lasting durability. Many industries trust our product. It reduces downtime and costs. You can install it easily. The pipe resists wear and corrosion. It handles high temperatures well. Our team designed it for reliability. Customers worldwide choose this pipe. It provides excellent value. We manufacture it with care. Each pipe meets strict standards. Use it for various applications. It outperforms traditional materials. Enjoy low maintenance needs. The pipe is lightweight yet strong. It fits many systems seamlessly. We deliver on time. Experience superior quality today.

Exceptional Product Features

The pipe has extreme hardness. Its HRC rating is over 85. This hardness beats most steels. It is close to diamond hardness. Wear resistance is outstanding. Our formula uses alumina ceramic. We add special wear-resistant materials. The process involves dry pressing. This creates high density. It also boosts toughness. Tests prove its wear resistance. It lasts 266 times longer than manganese steel. It outperforms high-chromiumcast iron by 171.5 times. corrosion resistance is excellent. The material is inorganic oxide. It has stable molecular structure. No electrochemical corrosion occurs. It withstands acids and alkalis. It resists salt solutions. Organic substances do not harm it. High temperature stability is great. installation is simple. The pipe is lightweight. It saves 20-30% steel compared to others. Thermal and mechanical shock resistance is good. Use welding or flange connections. This speeds up installation. It cuts down on costs.

| Ceramic patch wear -resistant pipe parameters | ||||

|---|---|---|---|---|

| Specification | Outer Diameter | Inside Diameter | Wall Thickness | Steel Pipe Thick |

| DN80 | 112-132 | 80 | 10~14 | 6~12 |

| DN100 | 132~152 | 100 | 10~14 | 6~12 |

| DN125 | 157~177 | 125 | 10~14 | 6~12 |

| DN150 | 182~202 | 150 | 10~14 | 6~12 |

| DN200 | 236~264 | 200 | 10~20 | 6~12 |

| DN250 | 286~314 | 250 | 10~20 | 6~12 |

| DN300 | 336~364 | 300 | 10~20 | 6~12 |

| DN350 | 386~414 | 350 | 10~20 | 6~12 |

| DN400 | 436-464 | 400 | 10~20 | 6~12 |

| DN450 | 486~514 | 450 | 10~20 | 6~12 |

| DN500 | 542~584 | 500 | 15~30 | 6~12 |

| DN600 | 642~684 | 600 | 15~30 | 6~12 |

| DN700 | 742~784 | 700 | 15=30 | 6~12 |

| DN800 | 842~884 | 800 | 15-30 | 6~12 |

| DN900 | 942~984 | 900 | 15-30 | 6~12 |

| DN1000 | 1046~1088 | 1000 | 15-30 | 8~14 |

| DN1200 | 1246~1288 | 1200 | 15-30 | 8~14 |

| DN1400 | 1446~1488 | 1400 | 15~30 | 8~14 |

| DN1600 | 1646~1688 | 1600 | 15-30 | 8~14 |

| DN1800 | 1846~1888 | 1800 | 15-30 | 8~14 |

| DN2000 | 2046~2088 | 2000 | 15~30 | 8~14 |

Ideal Applications and Use Cases

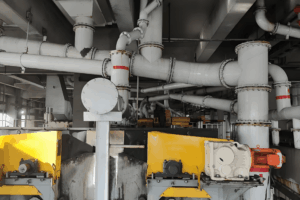

Mining operations benefit greatly. The pipe handles abrasive materials. It reduces replacement frequency. Chemical plants use it for corrosive fluids. It maintains integrity under harsh conditions. Power generation facilities rely on it. It withstands high heat and pressure. Cement manufacturing requires durable pipes. Our product resists wear from raw materials. Steel mills find it useful. It lasts longer in demanding environments. Water treatment plants choose it. It does not corrode easily. Oil and gas industries appreciate its durability. It performs well in offshore applications. Transportation of slurries is ideal. The pipe minimizes blockages. Food processing areas use it. It meets hygiene standards. Any industry with abrasion issues can use it. It is versatile and reliable.

Why Choose Our Ceramic Pipes

We have years of experience. Our factory uses advanced technology. We ensure high-quality production. Each pipe undergoes rigorous testing. We offer competitive pricing. Customer satisfaction is our priority. Our team provides excellent support. We deliver orders promptly. Custom solutions are available. Our products have international certifications. We use premium raw materials. Innovation drives our designs. Many clients give positive feedback. We help with installation guidance. Our warranty covers defects. Long-term partnerships matter to us. We respond quickly to inquiries. Global shipping is possible. Trust our expertise for your needs.

Conclusion and Call to Action

Upgrade to our ceramic pipe today. It offers unmatched benefits. You will see cost savings quickly. Contact us for more details. Place your order now. We are ready to assist. Improve your operational efficiency. Choose reliability and quality. Let us solve your pipe problems. Reach out via our website. We guarantee your satisfaction.