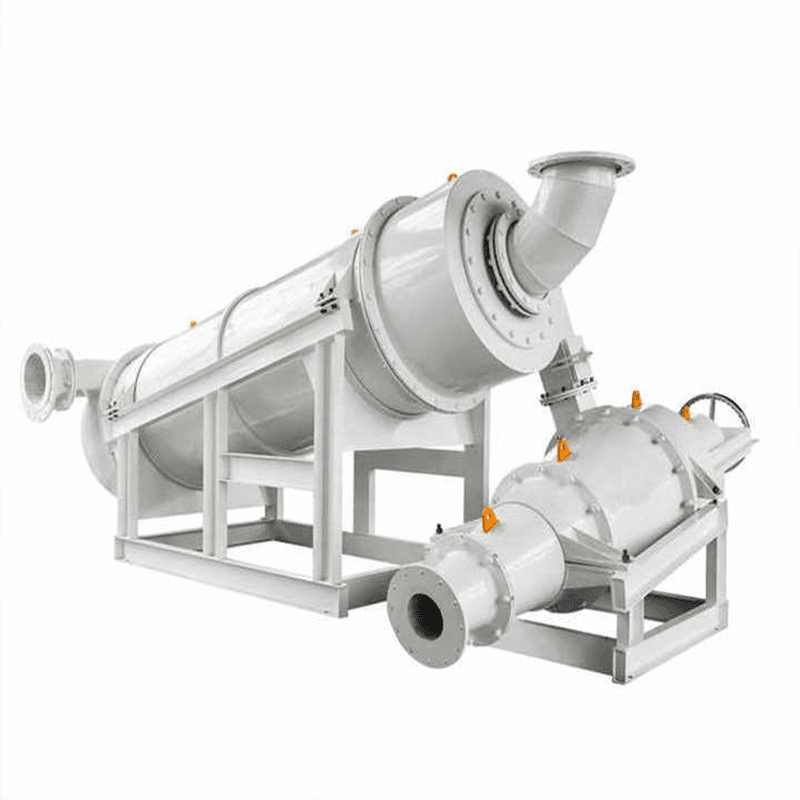

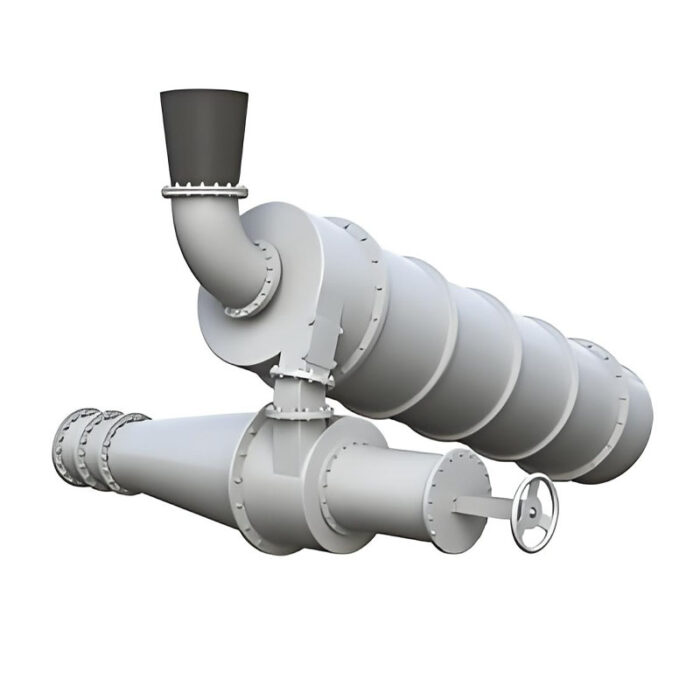

Introduction to Heavy Medium Cyclone

Heavy medium cyclones are vital equipment for mineral separation. Our heavy medium cyclone delivers excellent sorting performance. It ensures high precision and high efficiency. You can achieve accurate separation of materials. This results in three distinct products. These include clean coal, middlings, and gangue. Such capability enhances your plant output. It maximizes product quality and value.

The process system is remarkably simplified. Our cyclone uses a single medium for three-stage sorting. Multiple media systems are not required. Raw coal can be fed directly without desliming. This approach reduces operational complexity. It lowers overall costs significantly. Efficiency gains are immediate and substantial.

Operation reliability is another key benefit. Our cyclone incorporates wear-resistant materials. These materials offer extended lifespan. Stability is guaranteed during continuous use. Pressureless feeding minimizes energy consumption. Precise sorting leads to reduced emissions. This makes it an economical choice. It also supports environmental sustainability.

Product Parameters

| Specification, model and technical parameters of pressureless three products | ||||

|---|---|---|---|---|

| Specification | Feed particle size | Feed pressure | Processing power | separation size |

| 3WHZ500/350 | ≤20 | 0.05~0.08 | 35~50 | 140~180 |

| 3WHZ600/400 | ≤30 | 0.06~0.10 | 50~80 | 180~300 |

| 3WHZ710/500 | ≤35 | 0.08~0.12 | 80~120 | 300~420 |

| 3WHZ780/550 | ≤40 | 0.09~0.13 | 100~150 | 420~540 |

| 3WHZ850/600 | ≤45 | 0.10~0.14 | 120~180 | 480~620 |

| 3WHZ900/650 | ≤50 | 0.12~0.16 | 140~200 | 560~700 |

| 3WHZ1000/710 | ≤55 | 0.15~0.18 | 180~230 | 700~800 |

| 3WHZ1100/780 | ≤60 | 0.18~0.22 | 220~280 | 800~1100 |

| 3WHZ1200/850 | ≤70 | 0.20~0.28 | 260~350 | 1100~1400 |

| 3WHZ1300/920 | ≤80 | 0.22~0.30 | 320~400 | 1400~1600 |

| 3WHZ400/1000 | ≤90 | 0.28~0.38 | 400~500 | 1600~2000 |

| 3WHZ1500/1100 | ≤100 | 0.30~0.40 | 500~600 | 2000~2400 |

| Specifications, models, and technical parameters of the three pressure products | ||||

|---|---|---|---|---|

| Specification | Feed particle size | Feed pressure | Processing power | separation size |

| YTMC500/350 | ≤20 | 0.06~0.10 | 35~60 | 180~250 |

| YTMC600/400 | ≤30 | 0.08~0.12 | 50~90 | 250~370 |

| YTMC710/500 | ≤35 | 0.09~0.14 | 90~130 | 370~540 |

| YTMC780/550 | ≤40 | 0.10~0.15 | 110~160 | 540~660 |

| YTMC850/600 | ≤45 | 0.13~0.16 | 120~180 | 650~750 |

| YTMC900/650 | ≤50 | 0.15~0.18 | 160~200 | 740~840 |

| YTMC1000/710 | ≤55 | 0.18~0.22 | 200~250 | 840~1050 |

| YTMC1100/780 | ≤60 | 0.20~0.24 | 240~280 | 1050~1250 |

| YTMC1200/850 | ≤70 | 0.22~0.28 | 300~380 | 1250~1600 |

| YTMC1300/920 | ≤80 | 0.26~0.32 | 350~450 | 1600~1900 |

| YTMC1400/1000 | ≤90 | 0.30~0.40 | 450~550 | 1900~2300 |

| YTMC500/350 | ≤20 | 0.06~0.10 | 35~60 | 180~250 |

Key Features of Our Heavy Medium Cyclone

Our heavy medium cyclone provides superb sorting efficiency. It handles materials with high accuracy. The separation process is fast and effective. You obtain pure clean coal, middlings, and gangue. This high precision improves your recovery rates. It boosts overall productivity and profit.

A standout feature is the simplified process. Single medium enables one-pass three-stage separation. No additional media are needed. Raw coal is processed as received. No pretreatment like grading is necessary. This simplification cuts downtime and labor. It increases throughput and cost savings.

We ensure reliable and eco-friendly operation. The cyclone has durable wear-resistant parts. These components last long and perform steadily. Pressureless feeding reduces power usage. Accurate sorting decreases waste and emissions. Thus, it is both cost-effective and green.

Common Applications of Heavy Medium Cyclones

Heavy medium cyclones are ideal for coal preparation plants. Their high sorting efficiency suits fine coal separation. You can achieve precise product grading. This is essential for maximizing clean coal yield. Industries benefit from improved purity and revenue.

The simplified process applies to various mining operations. It allows direct handling of run-of-mine coal. This is useful in space-constrained sites. Large-scale plants see significant cost reductions. Operational workflows become smoother and faster.

Reliable operation makes our cyclone perfect for harsh environments. Mining and recycling sectors rely on its durability. Energy-saving features appeal to sustainable facilities. Lower emissions help meet regulatory standards. It is a versatile solution for many industries.

Why Our Factory is Your Best Choice

We specialize in high-quality heavy medium cyclones. Our products offer exceptional sorting efficiency. You get accurate separation for better results. This enhances your operational performance. Our focus on precision ensures customer satisfaction.

Our design emphasizes process simplification. This reduces your installation and maintenance costs. By choosing us, you gain a streamlined system. It integrates easily into your existing setup. We help you achieve higher efficiency with less effort.

Durability and eco-friendliness are our priorities. We use premium wear-resistant materials. These ensure long service life and stability. Energy-efficient operation lowers your bills. We support your green initiatives effectively. Our team provides reliable support and service.

Conclusion: Optimize Your Process Today

Invest in our heavy medium cyclone for superior sorting efficiency. It delivers high precision and reliable results. Upgrade your system to improve product quality. Experience enhanced performance and profitability.

The simplified process offers clear advantages. It reduces complexity and operational expenses. Adopt our solution for a cost-effective workflow. You will see immediate benefits in efficiency.

With eco-friendly and durable operation, our cyclone is a smart choice. It ensures long-term savings and environmental care. Contact us now to learn more. Let us help you achieve your goals. Take action today for a better tomorrow.