Introduction to Self Propagating Centrifugal Casting Tube

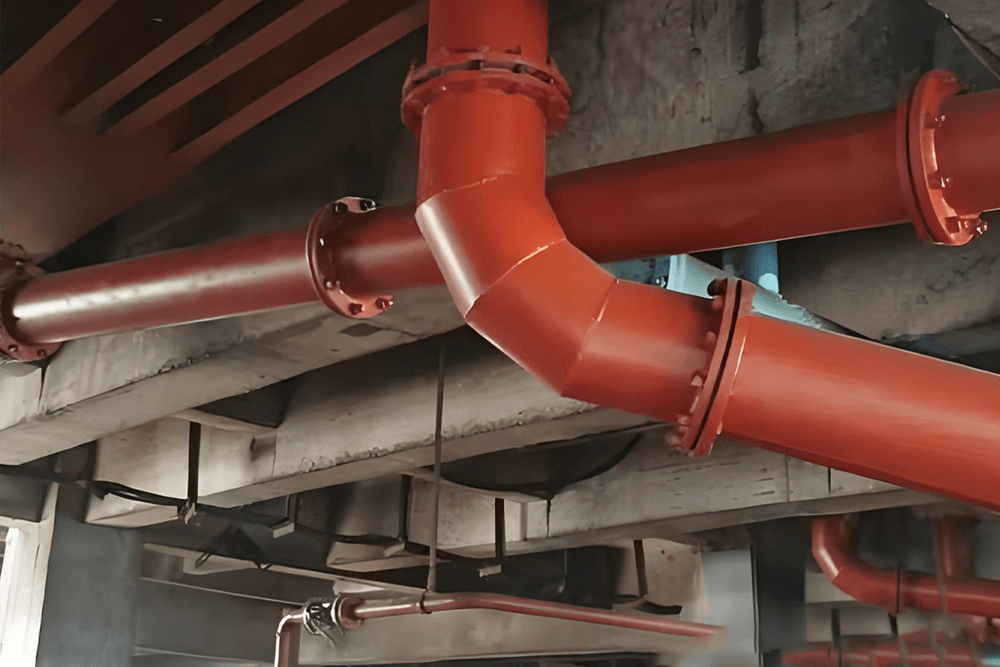

Welcome to our Self Propagating Centrifugal Casting Tube. This innovative product delivers outstanding performance. It is ideal for various industrial applications. Our tube excels in durability and efficiency. You will appreciate its long service life. It features excellent wear resistance. The product reduces overall project costs. Installation is straightforward and quick. We utilize advanced manufacturing techniques. Self-propagating reactions ensure quality. Centrifugal force creates a uniform layer. This tube handles extreme conditions well. It resists corrosion and scaling effectively. Many industries trust our solution. Discover the benefits today. Choose reliability and savings. Our team provides full support. Experience superior pipe performance.

Parameter

| Project | Hardness HVKgf/mm2 | Crushing strength ① Mpa | Specific gravity g/cm3 | Shear strength ② Mpa | Absolute roughness mm | Linear expansion coefficient ③ × 10-6K-1 |

|---|---|---|---|---|---|---|

| Ceramic steel pipe | 1100-1400 | 350-400 | 4.6-4.7 | 15 | Dn≤150 为 0.35 Dn>150 为 0.12 | 8.5-9 |

| 20 # carbon steel pipe | 149 | 411 | 7.85 | Hfgh | new 0.05-0.1 old 0.4-0.6 | 14-15 |

Superior Wear Resistance

Self Propagating Centrifugal Casting Tube offers exceptional wear resistance. This property extends product lifespan. It withstands abrasive materials easily. Mining operations benefit greatly. Power plants use it for ash transport. The dense ceramic layer resists erosion. You avoid frequent replacements. Maintenance costs decrease significantly. Operations continue without interruption. This reliability boosts productivity. Harsh environments pose no problem. The tube maintains integrity over time. Industries like cement and steel rely on it. Save money on upkeep. Enjoy consistent performance. Our tube outperforms competitors. Invest in long-term solutions. Trust our wear-resistant design.

Cost-Effective Engineering Solutions

Self Propagating Centrifugal Casting Tube lowers project expenses. Its lightweight design cuts costs. You save on support structures. Handling and transport fees reduce. Long service life means fewer replacements. Total investment drops noticeably. Compare it to cast stone pipes. Costs are similar or better. Against耐磨钢管, save twenty to thirty percent. Engineering budgets shrink favorably. Average expenses fall significantly. This efficiency pleases project managers. Allocate funds to other areas. Achieve more with less money. Our tube offers great value. Financial planning becomes easier. Embrace cost-efficient choices today.

Low Operating Resistance

Self Propagating Centrifugal Casting Tube ensures smooth flow. Low operating resistance is key. It minimizes energy consumption. Systems run more efficiently. Pressure drops reduce greatly. This leads to lower power bills. Pumps and motors work less hard. Equipment lifespan increases. You see improved performance. Industrial processes benefit immensely. Material transport becomes effortless. Friction losses are minimal. Operational costs decline over time. Enjoy reliable fluid handling. Our tube supports sustainable practices. Reduce your carbon footprint. Choose efficient pipeline solutions. Experience seamless operations daily.

Excellent Temperature Tolerance

Self Propagating Centrifugal Casting Tube handles wide temperatures. It operates from minus fifty to nine hundred degrees Celsius. Long-term use is safe. The material remains stable. Thermal expansion is low. Coefficient is six to eight times ten to the minus six per degree C. This prevents deformation issues. High heat applications work well. Cold environments pose no threat. Industries like metallurgy use it. Boilers and furnaces benefit greatly. You avoid thermal stress problems. Performance stays consistent. Safety improves significantly. Our tube meets extreme demands. Rely on its robust design. Trust in temperature resilience.

Corrosion and Scaling Defense

Self Propagating Centrifugal Casting Tube fights corrosion effectively. It also prevents scaling buildup. Harsh chemicals do not damage it. Water treatment plants appreciate this. The ceramic layer blocks attacks. Surfaces stay smooth and clean. Flow efficiency remains high. You reduce cleaning frequency. Maintenance intervals lengthen. Costly repairs avoid altogether. Industries with corrosive media benefit. Oil and gas sectors use it. Longevity increases dramatically. Operations run without hiccups. Protect your investment properly. Choose our anti-corrosion solution. Enjoy trouble-free service years.

Easy Installation and Maintenance

Self Propagating Centrifugal Casting Tube installs quickly. Its lightweight nature helps greatly. You save twenty to thirty percent steel. Handling is simple and safe. Welding and flange connections work well. No special tools needed. Labor time decreases significantly. Installation costs drop notably. The tube resists heat and impact. Transport and setup become easy. Projects finish faster. On-site adjustments are straightforward. Maintenance demands are low. Inspections occur less often. Teams work efficiently. Reduce overall project timelines. Our product simplifies your work. Embrace hassle-free implementation.

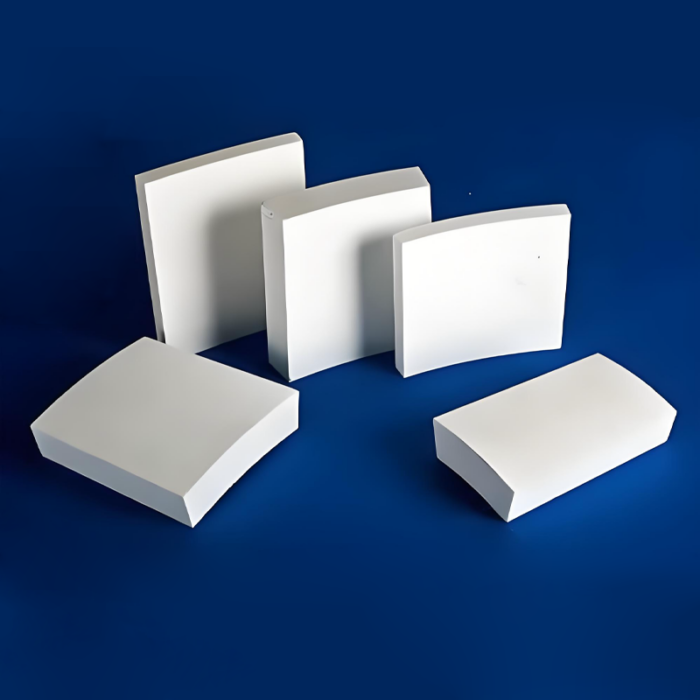

Advanced Process and Why Choose Us

We make Self Propagating Centrifugal Casting Tube with centrifugal casting. Self-propagating reactions reach over twenty-two hundred degrees Celsius. Centrifugal force forms a dense ceramic layer. It is uniform and strong. Customization is available. Sizes range from DN350 to DN2000. Thickness options are twelve to fifteen millimeters. Tolerances meet your specs. Why choose our factory? We have years of experience. Quality control is strict. We deliver on time every time. Our team offers dedicated support. Products undergo rigorous testing. Customer satisfaction is our priority. Trust our expertise and innovation. Partner with us for success. Contact us now to learn more.