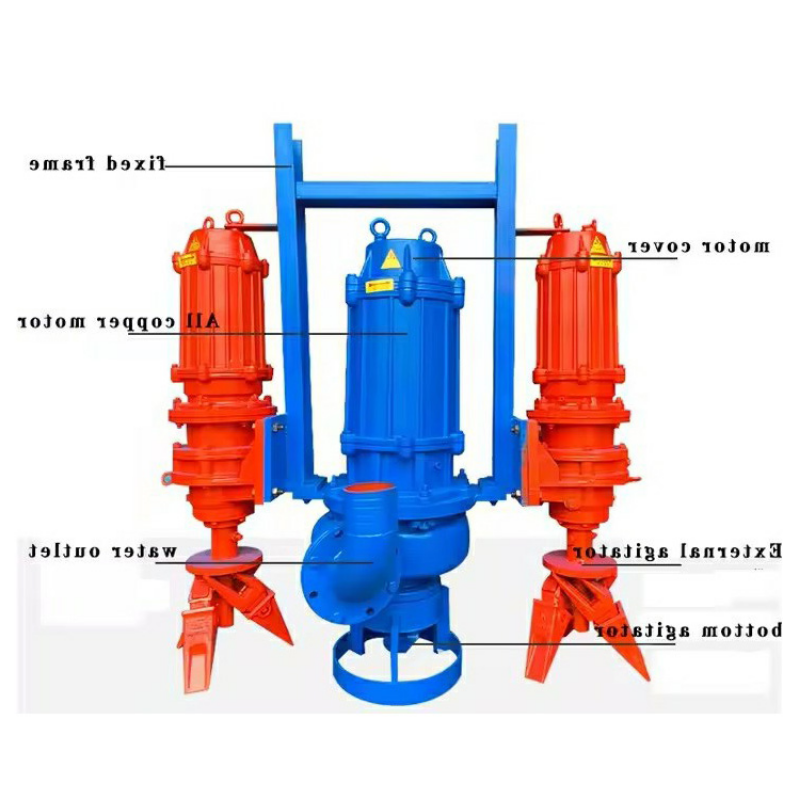

ZJQ Submersible Slurry Pump

Introduction

ZJQ submersible slurry pump has excellent material selection,advanced structure, wide overflow channel and strong sewage discharge capability.

lt is suitable for conveying liquids containing solid particles such as sand, coal slag etc.

lt is mainly used for transportation of mud liquids in enterprises such as metallurgy, mining, and thermal power plants .In addition to the main impeller, the water pump adds a set of agitating impellers at the bottom, which can spray the settled sludge into turbulent flow. The pump can achieve high concentration transportation

| Model | Capacity ( m3/h ) | Head ( m ) | Motor Power ( kw ) | Speed Rotation ( r/min ) |

|---|---|---|---|---|

| 40ZJQ8-12-2.2 | 8 | 12 | 2.2 | 1400 |

| 40ZJQ15-12-3 | 15 | 12 | 3 | 1400 |

| 50ZJQ25-15-4 | 25 | 15 | 4 | 1400 |

| 50ZJQ17-10-4 | 17 | 10 | 4 | 1400 |

| 65ZJQ71-25-11 | 71 | 25 | 11 | 1400 |

| 65ZJQ47-34-11 | 47 | 34 | 11 | 1400 |

| 80ZJQB0-18-11 | 80 | 18 | 11 | 1400 |

| 80ZJQ45-23-15 | 45 | 23 | 15 | 1400 |

| 1OOZJQ214-32-45 | 214 | 32 | 45 | 1400 |

| 100ZJQ293-24-45 | 293 | 24 | 45 | 1400 |

| 150ZJQ635-40-155 | 635 | 40 | 155 | 980 |

| 200ZJQ396-50-185 | 396 | 50 | 185 | 980 |

| 200ZJQ792-46-215 | 792 | 46 | 215 | 980 |

Structure

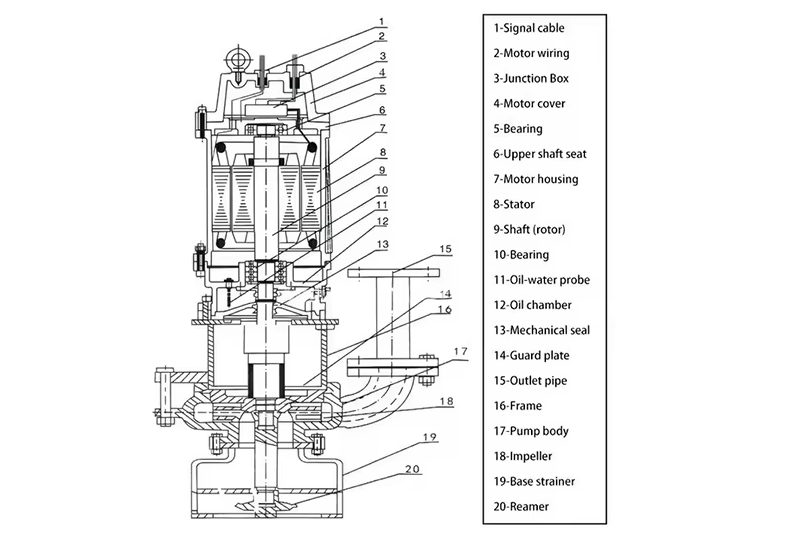

Innovative Dry Motor Design for Maximum Protection

Our submersible slurry pump features a dry motor construction. Moreover, the mechanical seal effectively protects the motor chamber. It reliably prevents high-pressure water ingress. Additionally, it blocks various impurities from entering. Consequently, the motor maintains optimal operating conditions. This design significantly extends the pump’s service life. Therefore, you achieve greater operational reliability even in demanding environments. Furthermore, this protection system reduces maintenance requirements. Ultimately, your operations continue uninterrupted.

Dual Impeller System for Enhanced Mixing and Extraction

Besides the main impeller, we include a specialized mixing impeller. This additional component actively stirs settled sludge at the bottom. It creates strong turbulence in the water. Meanwhile, the main impeller efficiently extracts the agitated mixture. Thus, this submersible slurry pump handles thick sediments effectively. As a result, you get complete basin cleaning with minimal residue. Moreover, the dual-impeller design ensures thorough mixing. Consequently, pumping efficiency improves substantially.

Wear-Resistant Components for Long-Lasting Performance

Key components like impellers use high-wear materials. These special materials offer excellent abrasion resistance. They also provide strong corrosion protection. Furthermore, the innovative design prevents clogging reliably. Consequently, the pump maintains powerful discharge capacity. It easily passes large solid particles without blockage. Therefore, this submersible slurry pump ensures continuous operation. Additionally, the wear-resistant parts last longer. Thus, you save significantly on replacement costs.

Superior Dredging Efficiency with Flexible Operation

The pump operates without suction lift limitations. Thus, it achieves high sediment removal efficiency. Additionally, dredging becomes more thorough and complete. Meanwhile, the mixing impeller contacts sediment directly. Moreover, submersion depth controls slurry concentration easily. Consequently, you obtain flexible density management. This submersible slurry pump adapts to varying site conditions perfectly. Furthermore, operation remains simple and intuitive. Therefore, operators achieve optimal results quickly.

Economic Advantages with Simplified Configuration

The system requires no auxiliary vacuum pump. Therefore, initial investment decreases significantly. Furthermore, installation becomes simpler and faster. Additionally, operating costs remain consistently low. Consequently, you save substantially on equipment expenses. This submersible slurry pump delivers outstanding long-term value. Moreover, maintenance needs are minimal. Thus, your total cost of ownership reduces considerably.

Versatile Applications Across Multiple Industries

This equipment serves wastewater treatment plants perfectly. It handles sludge removal effectively in municipal systems. Moreover, industrial plants use it for sediment cleaning regularly. Mining operations benefit from its robust performance consistently. Additionally, construction sites apply it for dewatering successfully. River dredging projects rely on its proven efficiency. Port maintenance teams choose this pump for routine operations. Consequently, this submersible slurry pump meets diverse industrial needs excellently.